B & D Murkin

UK main importers for

Le Tonkinois varnish

Flexidisc sander

Eberspacher Fuel supply & Fuel Faults 1

General

Often the only fuel related problem considered for Eberspacher problems is running out of fuel but there are many other reasons that are easily overlooked.

Eberspacher heaters use a pulsed fuel metering pump to supply tiny spurts of fuel, about 0.02ml per pulse, to the heater. The pump is pulsed by the Electronic Control unit (ECU), each time the pump pulses the solenoid makes a loud "tick". The pulse rate and pump setting determine how much fuel is supplied, there is no carburettor. Fuel is drawn by suction from the fuel supply up to the pump. Fuel flows into the combustion chamber where it is vaporized and mixed with air from the combustion air intake pipe and burnt.

The hot exhaust gasses pass through the inside of the heat exchanger and vent through the exhaust pipe.

It is important that pumps and fuel pipes are correctly installed as many faults can be caused by incorrect installation. Pump delivery volumes are preset during manufacture for the heater model so pumps should be the correct type but it may be possible to adjust others, see following page.

There are too many details to cover here, full details are in the manuals. Pipe details quoted on this page generally apply to D2 D4 and some similar heaters, check manuals for confirmation on other models.

Lower down this page shows fuel volume tests, Fuels 2 page shows pump testing and disassembling.

Fuel Problem page shows details of our practical fault finding when we had fuel problems on our heater.

Eberspacher recommend regardless of the season, run the heater every month for a minimum period of 15 minutes which will ensure that the fuel in the pump and lines to the heater does not gel and solidify. We usually only run ours once or twice during the Summer but we run on kerosene.

Although these pages are for Eberspacher diesel heaters Webasto use a similar fuel supply system so much of the general advice will also apply to Webasto heaters.

We welcome feedback and any additional advise you can add to these pages.

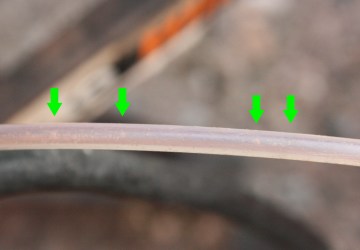

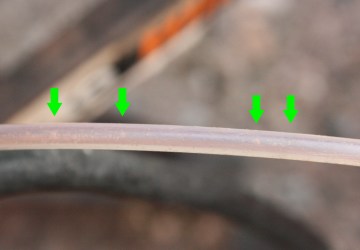

Normal air bubbles in fuel pipe are very small and about half an inch apart. It may take several starts to drop to this size. Some are too small to be visible in this photo.

More bubbles indicate a small air leak.

Very large bubbles indicate an air leak or lack of fuel.

Performing a Fuel quantity test

The fuel quantity test is an important check of the quantity of fuel delivered to the Eberspacher.

Fuel volume test method, D1LCC, D3LCC, Airtronic D2 D4 D5, Hydronic 10, DW4SC, DW5SC.

Disconnect the fuel pipe from the Eberspacher fuel inlet and insert it in a small container to catch the pumped fuel. The container can be a graduated 10 ml or 20 ml cylinder so the result can be read directly, or a bit less high tech, a small aluminium foil pie dish plus a 5 ml syringe, no needle, which should be available at any pharmacy for less than £1. Fuel will exit the pipe during the test in reasonably powerful squirts, if it trickles out it shows there is a problem. Switch the heater on and once pump starts let it run to bleed any air for about a minute, then switch off and empty container. Switch the heater on, the pump will start after about 60 seconds with a D2 or D4. Hold the end of the pipe in the container level with the glow pin while fuel is being delivered, between 90 and 110 seconds. We know of instances where it tested ok when held at a lower level despite there being a fuel supply problem. Once the pump stops switch off the heater and measure the quantity of fuel.

Note cc, ml and cm3 are the same volume.

Fuel quantity in cc (or ml) should be between: D1LCC 3.4 to 4.65, D3LCC 7.1 to 9.3, D2 3.7 to 4.4, D4 5.0 to 6.4, D5 8 to 10, D4WSC 7.3 to 7.9, D5WSC 8.5 to 9.0, Hydronic 10 9.1 to 10.2.

The fuel quantity for these models should not be affected by normal voltage variations.

If the fuel volume is low or out of specification check for blocked filter or pipes, air leaks, incorrectly installed pump etc.

High fuel volume is probably caused by incorrect fuel tap off point, see manuals, or incorrect pump.

Fuel volumes are not quoted for the Airtronic D2L or D4L

Low fuel volume can cause flame outs, see Faults page

High fuel volume can cause overheating shutdowns and wasted fuel.

We know one user bought a D1LCC which came with a D2/D4 pump (test result on Fuels 2 page)

Alternative test method.

If you are testing on your own and the heater start switch is remote from the heater you can alter the test method slightly for an Airtronic D2 and get an approximate indication.

Do not switch off after 60 seconds, let it continue until it stops after the first start attempt, empty the fuel into a spare container and use the second start for the fuel measurement. The quantity pumped by the D2 second start will be about 5% lower than on the first attempt as the number of pump strokes is reduced from 189 to 180. If the results show fuel volume is marginal redo the test properly the original way.

The D4 second start attempt is much shorter than the first so cannot use this method. We do not know about other models.

These time measurements were taken on our heaters to show how long you have between stages.

Air bubbles should be removed before measurement. Hold syringe upright and then press plunger in very carefully.

Too much pressure and fuel squirts out, needing another test.

Pump not clicking

People assume that because the pump is not clicking it is faulty and remove it, then most find it is not faulty.

When the heater is started the ECU makes a number of checks as described on the Faults page. If any of these pre-start checks fail the ECU aborts the startup and no fuel is pumped. Look at the Faults page first to eliminate those causes. Note also that pumping is delayed on modern heaters for up to a minute after switching on while the glowpin preheats.

If the heater passes the pre-start checks and the blower speeds indicate everything is proceeding as it would normally but the pump is not clicking go to the Pump Mechanical section below.

Pump clicking but no fuel delivered to heater

Check if you have run out of or are simply low on fuel, a tank pick up tube can be 50 mm or more above the tank bottom. This ensures there will be enough fuel left to run the engine and prevents crud in the bottom of the tank from being picked up. On one camper van the tank held diesel for about 250 miles but the heater stopped working after 200 miles.

If the fuel pipes were empty before starting check if purging of air is complete.

Check the fuel lines and connections for air leaks

Check all clips are tight.

Check condition of rubber sleeves, they swell and can become porous as they deteriorate.

Check for blockages in pipes, more details lower on this page.

In very cold weather any water in the fuel can freeze. Most UK fuel sold at the pumps is winterised from September onwards, summer fuel will wax up at relatively mild temperatures.

Check the fuel pick-up pipe, on some non Eberspacher types the tube pushes into the upper part and can have an air leak or it might have fallen off.

Check the fuel filter in the base of the pump.

Remove the pump and bench test it as described on Fuels 2 page.

Fuel quantity test

The fuel quantity test is an important check of the quantity of fuel delivered to the Eberspacher heater.

Combustion depends upon the fuel / air mixture being within prescribed limits. The fan speed determines the amount of air entering the burner, the pump rate and setting the amount of fuel.

Do this test if you suspect a fuel problem. It checks for blocked fuel filter, blocked or kinked pipes, loose connections, air leaks, faulty pump, or incorrectly installed piping. If the pump does not deliver sufficient fuel it can cause non or difficult starting, flame-outs and white smoke. Too much fuel can cause similar starting problems, overheating, black smoke and the heater to clog up.

Details of the test are on this page. Pump adjustment details are on the next page.

Water in diesel fuel

Diesel fuel will always contain some water when sold. As the fuel level or temperature changes air enters the tank through the vent, condensation then forms when the air cools increasing the water in the tank.

The water– fuel interface at the tank bottom is an environment that encourages biological growth which can clog filters and prevent fuel flow to the heater.

Diesel floats on top of water so pickup pipes should not reach the bottom of the tank. Even then as the water sloshes about it can sometimes reach the end of the pipe and be picked up and cause intermittent and puzzling flame outs.

If water is found in the fuel siphon it off from the lowest point of the tank until clear fuel is siphoned up.

Fuel Degradation

Diesel fuel starts to deteriorate the moment it leaves the refinery. As it ages during storage, it creates particles and a black sludge that accumulate in the tank. The diesel visibly darkens.

Debris can be disturbed when new fuel is added or when fuel sloshes around in the tank.

The cetane value of the fuel also drops as it ages and can drop so low it will no longer ignite in the heater.

More information is in the Eberspacher technical bulletin 281.

Priming the fuel supply

If the fuel pipes are empty the pump has to purge the air from them before fuel can reach the heater. With a thin pipe this often takes two start attempts, with a larger or far longer pipe it can take 5 or more restarts and up to 30 minutes to start. Manual priming by dabbing temporary wires on a battery can be done but it is not very practical. As a comparison we estimate one start attempt on a D1LCC can give over 300 pulses.

Cold weather

Fuel thickens as the temperature drops, if it combines with debris in the fuel filter it can restrict the fuel flow.

Any water trapped in the pump or filter can freeze and block the fuel feed and seize up the pump.

Water can be trapped in the exhaust pipe and freeze which blocks the exhaust gas flow. This can be a problem on boats where the outlet pipe is higher than the heater so condensation cannot drain. Some fuels do not perform well at low temperatures.

Fuel flow and air / fuel leaks

With transparent fuel pipe tiny air bubbles are usually visible in the fuel as it pulses towards the heater which can be a very useful diagnostic check on fuel flow.

Dereks calculations on 1.5mm internal diameter piping show fuel moves just over a cm per pump stroke giving the bubble spacing. They are present even if there are no air leaks. Thanks to Jon D for explaining these bubbles are created by cavitation when the pump creates a vacuum. If there are a lot more bubbles than those shown in the picture it can indicate an air leak. However we have noticed it does take a long time for bubbles to drop to this amount and size after the pump has been primed, it can take quite a few successful starts, the bubbles gradually diminish. Larger bubbles can be due to a serious air leak but are more often caused by lack of fuel.

If the pipe is disconnected fuel spurts out quite strongly, if it just trickles out there is a problem. The small quantity of fuel pumped, 0.02ml per stroke means small air leaks in the pipe before the pump can reduce the amount of fuel pumped.

The pipe before the pump is under suction so no fuel will leak out to indicate problems.

Leaks in the pipe between the pump and heater can result in fuel leaking.

Usual causes are holes in the rubber connecting pipes or badly sealed joints. If the rubber connecting pipe is leaking renew it together with the clamps, just tightening the bolts is often unreliable and the fault reappears. We have found clamps have to be very tight to give a good seal but don't overtighten and sheer the bolts or bend the outlet.

Tip - New jubilee type clips can be extremely stiff and need so much turning torque the metal pipes on the pump and heater can bend. I put the new clamp on the shaft of a screwdriver and tighten it down until it is smaller than the rubber tube before loosening. It is then much easier to tighten when fitted on the pipe.

Rubber connecting pipes with too large internal diameter can also give poor seals.

Cheap pipe is soft and kinks easily blocking the supply.

The rubber connecting pipes can cause air leaks.

Fuel pipes and pickup

We found that although you can blow through completely empty pipe it becomes impossible to do so with even a small amount of fuel in the pipe. This can cause users to wrongly think the pipe is blocked.

If the pipes are blocked it is normally because the heater has not been used and the fuel has turned to jelly. Skip from Tennessee USA attached a small clear gas line to the hard plastic fuel line, filled it with acetone (alternative solvents like carb cleaner can be used) and let it sit for about an hour. The fumes and fluid would have softened the blockage before he applied low air pressure to force the fluid through the blockage. Then he flushed the line with diesel.

The rubber connecting sleeves can swell when they deteriorate.

Carbon build up can obstruct the fuel flow where it enters onto the glow-plug screen. In some cases the heater metal fuel pipe can be completely blocked. This is usually at the end near the screen and can be caused by not allowing the heater to go through its cool down cycle.

If the heater takes fuel from the main tank a separate fuel pickup pipe is normally used.

The end of the pickup tube is normally cut so it is between 1 and 4 inches short of the tank bottom. This ensures there will be enough fuel left to run the engine and prevents water and crud in the bottom of the tank from being picked up. This can cause users to think the heater is faulty when the heater stops due to lack of fuel as there is still fuel in the tank. The pipe on some types of pick up tubes is a push fit into the upper part and this can cause air leak problems. If the pickup pipe is too large the fuel may trickle back.

Blockages can occur in the pipes but are most likely at the pickup, the filter or connecting sleeves.

An air compressor or bicycle pump will clear pipes, we use one to remove the fuel from our temporary testing pipes before storing them.

Drilling a vehicle's plastic tank will void its approval. You may have to replace the cartridge type fitting with one from Eberspacher designed for that vehicle. Plastic swarf created during drilling floats on the fuel surface with obvious consequences.

Fuel pipe from the pump to the Eberspacher D2 is usually hard fairly clear plastic, 4 mm outer and 1.5 mm or 2 mm internal diameter. Maximum height lift for a D2 from the pump to the Eberspacher is 2 m. The pipe from the pump to the fuel tank is usually black hard plastic 5 mm outer and 2 mm internal diameter. Maximum height lift from the bottom of the tank to the pump is 1 m. The proper fuel pipe is difficult to kink or compress. Do not use cheaper soft plastic pipe which can kink badly. Do not crush the pipe when cutting. A pipe with a burr or sharp end can slice into the rubber as it is inserted forming a flap, photo on the Faults page. Large diameter fuel pipes can cause several problems including not priming the pipes, non starting and flame-outs. A 1 m length of 1.5 mm internal diameter pipe is filled by nearly 2 ml of fuel. The same length of pipe with 4 mm internal diameter would hold 7 times that amount and would take 7 times as many pulses to prime. This is why we always use the small diameter pipe, Ebay lists 2 mm internal diameter Eberspacher fuel pipe. Where pipes are joined they should butt against each other inside the rubber connecting sleeve, gaps can trap air bubbles.

There are restrictions on teeing from the existing engine fuel supply pipes, read the Eberspacher manuals carefully. There is one statement in some of the Eberspacher installation manuals about gravity feeding that is not fully explained and so could be misunderstood. Gravity feeding to the pump is ok, gravity feeding without a pump is not allowed. Maximum height of fuel above pump is 3 m.

Marine installations must use metal pipes and comply with all regulations.

Fuel leaking from exhaust

We occasional receive enquiries about garage mechanic or DIY installations where fuel leaks from the exhaust with the heater switched off. This is always a new installation where the fuel connection has been tapped from the existing fuel supply pipes.

Fuel must not be taken from a point under pressure or it can be forced past the Eberspacher pump.

Look at the Eberspacher manuals for details on correctly installing the fuel supply.

Flame-outs

If insufficient fuel reaches the Eberspacher the flame will extinguish and the flame-out causes the heater to shut down. The most common reasons for restricted fuel flow are blocked fuel filter, kinked pipe, air leaks, air lock or running out of fuel. Water in the fuel collects in the bottom of the tank, as this sloshes about it can be picked up replacing the fuel. Unsuitable fuel can cause flame-outs at low temperature particularly at the lowest heat setting. Flame-outs can also be caused by a clogged glowpin screen, blocked breather hole, heavy carbon deposits as well as blockages in the combustion air flow or exhaust.

Fuel pumping rates

The pump rate changes, usually together with the fan speed, with each heat setting.

Sometimes it may be useful to know at what setting the heater was operating when a fault occurs.

Fan speeds where known are quoted on the Faults page but the fan may not be accessible.

The manuals do not give pump rates so we have no figures for most heaters, details will be added here later if we measure them.

D2 low 80, med 121, High 188, Boost 220 strokes per minute.

D4 low 104, med 201, High 306, Boost 411 strokes per minute.

Fuel types and suitability

We have no expertise on fuel types so I am grateful for the specialist advice we received on suitable fuels for Eberspacher heaters. Most fuel sold at the pumps in the UK is winterised from September onwards and therefore should be OK for winter use, untreated fuel will wax up at relatively mild temperatures.

For all fuels good housekeeping is essential, modern fuels do not store like they used to.

Essentially Eberspachers will run on all of the fuels described provided there are no other issues.

Road diesel - specification BS EN 590, often referred to as white diesel or Derv, very expensive.

Red diesel - This is actually Gas Oil.

Before January 2011 'red diesel' was normally High Sulphur Gas Oil (also called 35 second oil, household heating oil). This was mainly used for agricultural and off road plant and you may still find old forum articles describing problems. The causes were investigated and solved in the Eberspacher technical bulletin 281.

From January 2011 fuel regulations changed so supplies now should be:

Ultra Low sulphur Gas Oil (ULSGO) with up to 7% bio for use in all off road machinery.

Ultra Low sulphur Gas Oil (ULSGO) with no bio fuel added, intended for use in Inland waterways and marine estuaries. However there is no guarantee if you own a boat that you wont be supplied the 7% bio fuel. It is now illegal to supply or use high sulphur gas oil on the inland waterways, it is still permitted for sea going boats.

Kerosene (Paraffin) - Premium Kerosene is known in the UK as Paraffin. Earlier manuals list paraffin and it is suitable but often difficult to obtain cheaply..

Domestic central heating oil - There are two types of domestic heating oil, 28 and 35 second.

Standard Kerosene to BS2869 Class C2 is a heavier distillate than Paraffin. Also known as 28 second fuel, this is a lighter alternative to standard heating oil (Gas Oil) and burns much more cleanly with low sulphur content.

We are now running our own Eberspachers on 28 second fuel (see below).

35 second oil is High Sulphur Gas Oil as mentioned above. In Germany it is sold as Heating oil EL.

Biodiesel, also called FAME (fatty-acid methyl ester), is made from animal fats or vegetable oils.

The table below shows Eberspacher bio diesel compatibility, if you are unsure about suitability contact Eberspacher or do not use bio fuel.

Which fuel do we use?

After problems when we bought some bad red diesel before it changed in 2011 we tried Kerosene, standard 28 second central heating oil. At that time the heater was very close to needing a 2000 hour service and was smoking. As soon as we changed there was a significant improvement, it burns cleanly with virtually instantaneous starting even in cold conditions. The smoking stopped and despite running on lowest heat setting most of the time for about a further 6000 hours the D2 has not shown any signs of needing a service. Derek highly recommends Kerosene.

An Eberspacher technical representative told us that the Ultra Low Sulphur Marine Gas Oil which replaced the old red diesel burns almost as clean as premium kerosene (paraffin) or road diesel so he advises it is not worth fitting a separate tank for kerosene. It may be difficult to find a kerosene supplier for small quantities, most only deliver and specify at least 100 litres. Our previous supplier W Powell in Bridgnorth closed down.

James Pickstock Ltd., Meifod, Powys, SY22 6GZ, 0800 859 5043 sell small quantities from their pump at about 44p per litre (Dec 2016).

Hyde Lane Filling Station, Chelmsford, CM3 4LP 01245 222121. 64p ltr 2017.

If you find other central heating oil suppliers who can sell in small quantities tell us and we will list them here.

Biodiesel compatibility

Heater Model |

Heater-No

|

100% FAME Operation

Note 1

|

Operation with road diesel which currently contains

10 to 12 % Biodiesel

|

|

AIRTRONIC D2 / D2 Camper

|

25 2069 05 00 00

25 2326 05 00 00

|

No

|

Yes Note 2

|

|

AIRTRONIC D4 12V / D4 24V

|

25 2113 05 00 00

25 2114 05 00 00

|

Yes

|

Yes Note 2

|

|

AIRTRONIC D4S 12V / D4S 24V

|

25 2144 05 00 00

25 2145 05 00 00

|

Yes

|

Yes Note 2

|

|

AIRTRONIC D5 12V / D5 24V

|

25 2361 05 00 00

25 2362 05 00 00

|

Yes

|

Yes Note 2

|

|

AIRTRONIC D3 Camper / D4 Camper / D4 Camper plus

|

25 2317 05 00 00

25 2318 05 00 00

25 2327 05 00 00

|

Yes

|

Yes Note 2

|

|

HYDRONIC

D4WSC / D4WS / D5WSC /

D5WS

|

All versions

|

No

|

Yes Note 2

|

|

HYDRONIC D 5 W S

|

25 2146 05 00 00

25 2218 05 00 00

|

Yes

|

Yes Note 2

|

|

HYDRONIC 10 / D 9 W

|

All versions

|

No

|

Yes

|

|

HYDRONIC 16/24/30/35

|

All versions

|

No

|

Yes

|

|

Air heaters D1LC compact /

D3LC compact / D3LP compact / D5LC

|

All versions

|

Yes

|

Yes,

probably also Note 2

|

|

Air heater D8 L C

|

All versions

|

No

|

Yes

|

Note 1 Suitable for operation with FAME according DIN EN 14214 in flowing capable condition.

(restricted output or may not work below 0°C)

Note 2 Operation of the heater with up to 10% more biodiesel added to the manufactured road diesel without restriction is possible, ie heater can work with about 20% total. We think the D1LC compact heater group should also be marked with Note 2, it was missing on the copy we obtained.

These instructions given in the AIRTRONIC D4 manual probably also apply to any of the models capable of using biodiesel:

Operation of heater with mixtures greater than 10% is restricted during periods of temperatures below 0°C.

Vent hole must be cleaned every 500 hours (twice a heating season assuming 1000 hours of operation annually). Atomising Screen must be replaced every 500 hours. Heater must be run for 30 min on high heat with regular diesel fuel once every 500 hours if mixtures above 50% are used. When using 100% biodiesel, the heater should be operated twice a year with diesel fuel (in the middle and at the end of a heating period) to burn off PME deposits. Let the vehicle tank run almost empty and fill with diesel fuel without any biodiesel. While running on this tank filling, switch the heater on 2 to 3 times for 30 minutes at a time at the highest temperature setting.

Biodiesel produces about 10% less heat per litre than normal diesel and poor oxidation stability means additives may be needed to improve storage conditions. Biodiesel is an excellent medium for microbial growth which is accelerated by water so special care must be taken to remove water from fuel storage tanks to avoid sediment buildup, premature filter clogging or storage tank corrosion. Diesel engines & heaters that are not designed for biodiesel can suffer from filter clogging, coking and rubber seal damage.

Home made or roadside bio fuels are very different to EN 14214 spec oil.

Fuels not recommended for Eberspacher heaters

Supermarket vegetable oil (New or Used frying oil) unless properly processed into FAME.

Fuels mixed with used oil.

The amount of money saved on these fuels will be insignificant compared to your additional servicing and repair costs.

|

Heater Model

|

Switch

on

|

Try 1

Pump start

|

Try 1

Pump stop

|

Try 2

Pump start

|

Try 2

Pump stop

|

Fan

stop

|

|

|

mm:ss

|

mm:ss

|

mm:ss

|

mm:ss

|

mm:ss

|

mm:ss

|

|

Airtronic D2

|

00:00

|

01:10

|

02:35

|

04:45

|

06:15

|

10:15

|

|

Airtronic D4

|

00:00

|

01:10

|

03:00

|

03:20

|

04:30

|

08:30

|

|

D1LCC

|

00:00

|

00:30

|

02:00

|

02:30

|

03:55

|

07:55

|

The easiest way to measure the fuel volume is in a measuring cylinder.

Cheap 10 ml one used here, £1 Ebay.

My D1LCC fuel volume test result 4 ml.

Alternatively use a syringe.

Old foil pie dish makes an alternative container.

The Tuna can just made the dish easier to handle. The fuel spurts out under pressure so take care to catch all of it. Tilt dish before sucking fuel into the measuring syringe.

A syringe can give better accuracy than a measuring cylinder, both are acceptable.

5 ml syringe bought from local pharmacy.

Alternative source including other sizes is Ebay.

Some users worry if the test volume is not close to the middle figure, eg with an Airtronic D2 about 4 cc, and think something is wrong. Any pump within that quoted limit of 3.7 to 4.4 cc should work with any Airtronic D2 heater so if the pump measures 3.7 cc it passes the test and is ok.

A pump does not simply work ok at 3.7 cc and then fail to work as soon as it drops outside the limit to 3.6 cc. Outside the limits is an area of uncertainty. Depending upon how far out of spec the pump is, it could work ok with some Airtronic D2 heaters but not others, it might only work with a heater in good condition, it might work only with some types of fuel etc. It also could increase the rate of carbon buildup needing more frequent servicing. If the fuel quantity result is below specification Eberspacher recommend that the fuel pump be replaced only if the heater repeatedly flames out during operation.

If the wrong amount of fuel is delivered and all other causes except the pump have been eliminated check the pump clamp fixing bolt has not loosened allowing the pump to move to horizontal.

It may be possible to adjust the pump by slightly altering the ball valve spring tension. One method is to adjust the small nuts, make sure they are secure so cannot undo with vibration.

Any change will require several fuel volume tests. The adjustment range is limited. Do not expect a 3.1 - 5 kW pump to adjust to match lower heat pump versions.

Older models such as D1L, D3L, D1LC, D4W and D5W require the glowpin to be disconnected during part of the test and their readings are voltage dependent so are not covered here, look at the manual for detailed instructions and their fuel volume graphs.

We had a fuel fault on Dereks D2 caravan heater that required detailed investigation.

We have documented the process as an example of practical fault finding.

Fuels 2 page continues with fuel pumps problems and dismantling.

Fuels 3 page practical fault finding example